Greek God, KRATOS, is the personification of Strength and Power in Greek mythology. This ethos has defined the direction of the KRATOS brand.

KRATOS came into conception through a group of engineers with 25+ years of private label design and manufacturing turbo systems for various house-hold name performance brands. These engineers saw a untouched segment in the high end European market for True OEM Style Dual Ceramic Ball Bearing Turbo System Manufacturing and through that revelation the KRATOS brand was born.

KRATOS systems are forged from the finest raw materials and assembled with strenuous attention to detail. Every component is purposefully designed and engineered-in-house and tested to extreme standards. KRATOS is The Only True Dual Ceramic Ball Bearing OEM Fit CORE-LESS Turbo System Manufacturer.

KRATOS aims to provide exclusive turbo systems for premium European performance vehicles. This goal is achieved through pride and purity of engineering as well as uncompromised use of top tier materials and manufacturing methods.

KRATOS was recently acquired by Global Motoring Group LLC, not to be confused with racing company GMG. This has further emphasized the focus of the KRATOS brand is to provide OE fit turbo solutions to top tier European performance cars.

Power and Results:

Testing:

Product prototypes have been in testing through 20k+ miles of daily driving at 750whp+ on beta test vehicles. In addition, KRATOS was approached by Strom Motorsports road racing team due to the inefficiencies and failures of the factory turbos they had experienced. Strom Motorsports recently took first place in the GT4 class at the Bathurst 12HR. Durability and endurance testing has primarily been completed Strom’s 25HR endurance M4 race car as well as their time attack M4.

Power:

List of modifications

Stock Engine

Stock Intercooler

Downpipes

Intakes

Spec Stage 2+ Clutch

Fuel-It PI

Maximum PSI Crank Hub

BootMod3

HCP Custom Tune

KRAS55Bi Turbo System (Standard Billet Wheel Option)

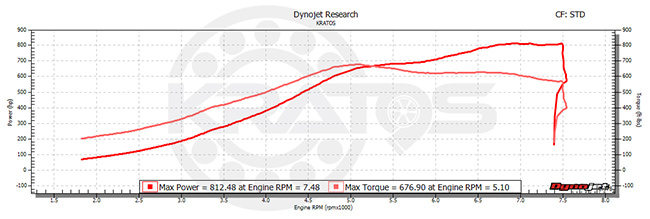

This Dyno Graph depicts the capability of the KRAS55Bi on a stock BMW S55 engine with the supporting modifications listed above at 32psi on E85 fuel. Notice how power continues to climb to the rev limiter which is a results of the compressor wheel, turbine wheel, and manifold A/R ratio design. The goal was to achieve 800whp on a stock engine safely while limiting midrange torque and horsepower for the safety of the connecting rods. More boost or timing was not applied to the stock engine for higher horsepower figures as durability and reliability are one of the main focuses of the KRATOS brand. It’s imperative that the test vehicles go through the proper sequence of durability testing at each tested power level before increases in power are applied. As KRATOS has been working very closely with BM3 and HCP tuning, with a built engine and cylinder head the KRAS55Bi will be capable of supporting up to 900whp with the proper tuning.

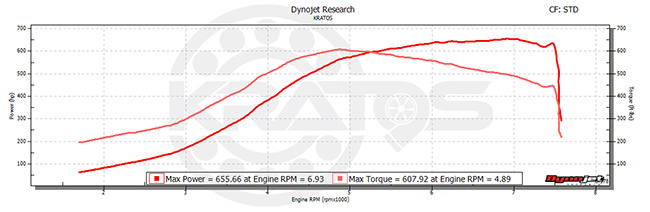

This Dyno Graph depicts the capability of the KRAS55Bi on a stock BMW S55 engine with supporting modifications listed above on 93 octane fuel only. As 93 octane is a much hotter burning fuel, along with that comes higher egt’s at given boost levels as well as a lower detonation ceiling. With that in mind, HCP Tuning devised a custom tune as boost and timing are tapered in the upper rpm to increase reliability and repeatability of power.

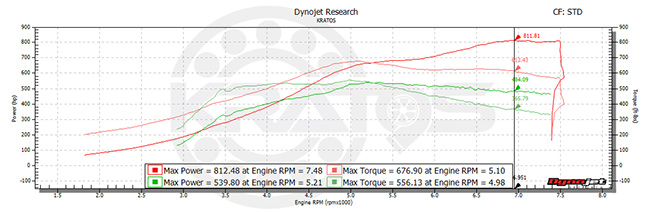

This Dyno Graph depicts the differences in power between the same BMW S55 engine on stock OEM turbos E30 Fuel Only with all modifications listed above without Fuel-It PI vs. KRAS55Bi on E85. There are other S55 that have made more power with stock turbos and stock fuel system, however this is the power that was made on the same vehicle which is why this data was used. Notice at 6900rpm there is a Difference of 327whp between the stock turbos and the KRAS55Bi. These figures are used for reference only, but they do give the end user an idea as to the difference of power that can be achieved when upgrading from a stock OEM turbo system on E30 to a KRAS55Bi on E85.

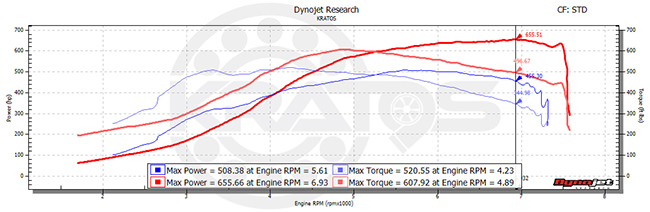

This Dyno Graph depicts the differences in power between the same BMW S55 engine on stock OEM turbos 93 octane fuel only with all modifications listed above without Fuel-It PI vs. KRAS55Bi on 93 octane fuel only. Notice at 6900rpm there is a Difference of 200whp between the stock turbos and the KRAS55Bi. These figures are used for reference only, but they do give the end user an idea as to the difference of power that can be achieved when upgrading from a stock OEM turbo system on 93 octane fuel only, to a KRAS55Bi on 93 octane fuel only.

Many BMW S55 owners have come to accept that fact that owning a FBO S55 with hybrid turbo upgrades limits them to approximately 700whp before running into connecting rod failures. The introduction of the KRAS55Bi proves that early connecting rod failure on stock engines is more a result of high exhaust back pressure along with extreme torque demands rather than a pre-mature mechanical limit of the rotating assembly based on data from several high mileage 750+whp beta test vehicles. The shape of the dyno curves listed above are a visual representation of the KRATOS Engineering Team’s success at disproving this fact.

Technical Summary:

Ceramic Ball Bearing Cartridge (Patent Pending):

KRATOS ceramic ball bearing technology encompasses industry leading technology in an OE fitment package. The use of ceramic ball bearings in true OE fit cartridges is entirely unique to KRATOS. This translates into ease of ownership and increased performance for the end user.

5x the service life of steel ball bearings.

Significantly lower operating temperatures than steel ball bearings.

Increased efficiency and thrust load capability.

Near frictionless operation requiring minimal oiling.

Heightened transient response.

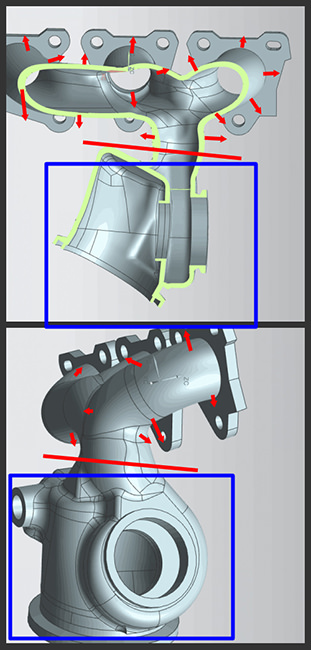

One Piece Turbofold (Patent Pending):

The cornerstone of the KRAS55 line of turbos, the completely re-engineered one piece turbofold is a part of the reason of safe power can be achieved. The turbofold reduces backpressure significantly, making engine operation at higher output safer and more reliable. In testing, data proved a 1.1:1 Backpressure rating at 32psi. A car making 32psi of boost would see 35.2psi of pressure on the manifold side. This allows for the engine to cycle without additional stress of vacating spent exhaust through a manifold with high resistance. If not addressed, excessive back pressure causes undue stress resulting connecting rod failures as well as loss of power and engine efficiency.

Mathematically matched A/R ratio.

Reduced heat and increased turbine efficiency.

Smoother internal runner transitions.

Increased runner diameter.

Computational Fluid Dynamics modeling software tested.

316 Stainless Steel.

OEM Fitment and Core-Less Design:

The integration of ceramic ball bearing technology into true OEM fitment is unique to the KRATOS brand. Like all other KRATOS line of products to follow, the KRAS55 series retains use of factory oil and water lines without use of adapters of any sort. Many customers may weigh downtime and core usage as important factors in their buying decision. KRATOS products allow customers to retain their cores for whatever use they prefer and create no downtime other than installation.

CORE-LESS

Utilization of OEM Oil + Water lines.

Full reversibility.

Full compatibility with OEM fit aftermarket parts

S55 Specific Inlets:

The factory S55 turbo inlets at their narrowest point have an internal diameter of 42mm. This poses a problem if a compressor wheel with a larger inducer diameter is used. To address this, all KRAS55 turbo systems include a set of custom designed 4 ply silicone inlets as well as a matched ported billet aluminum elbow which are designed to support flow capabilities of even the larger wheel options.

Direct fitment to OEM crankcase ventilation and intakes.

Custom Designed 4-ply silicone inlets.

Polished and match ported billet aluminum elbow.

Compressor Wheels:

KRATOS compressor wheels are in a league of their own. Each compressor wheel is designed and tested in house for each specific application in mind. These compressor wheels will only be found on KRATOS products and hundreds of hours have been spent on testing and design in order to match the intended use. KRATOS also performs shaft speed testing to ensure that compressor designs are not being run beyond their efficiency range or flow capabilities..

There are currently two options for compressor wheels on KRAS55 turbo systems.

KRAS55Bi: 850+whp

Forged Billet Aluminum

3rd order Geometry Design

Point Milled Manufacturing

For those who intend on keeping their internals stock, this may be the best option. This system is capable of supporting 850whp+ and allows for safer and reliable operation over 700whp on the stock engine.

KRAS55Ti: 1,000whp+

Forged Billet Ti6Al4v Titanium (Grade 5)

3rd Order Geometry Design

Point Milled Manufacturing

This wheel is intended for use on built motor high output setups. Titanium’s higher tensile strength over that of aluminum allows for more aggressive design characteristics. The Titanium material is also great for road race or endurance racing applications where HCF (High Cycle Fatigue) can pose issues. More information and data results will be available as release of the KRAS55Ti approaches.

Reviews

There are no reviews yet.